Highly Porous Carbon Products to Support Biofuels Production

Partners

GlucanBio, University of Wisconsin, Princeton

Sponsor

Department of Energy EERE Bioenergy and Technology Office– BETO EE0008353

Synopsis

The goals of this project were to separate biomass into high purity streams of cellulose, hemicellulose, and lignin in an integrated process to enable efficient and cost-effective downstream conversion processes. To that end, we successfully demonstrated an integrated biorefinery with high yields high purity fractions and produced high-value carbon products, specialty chemicals, and fuels. We achieved our goal using lignocellulosic biomass from various sources, fractionated under mild conditions using a biomass-derived solvent, γ-valerolactone (GVL), and water mixture, and recycled throughout the refinery process. We produced high-value products and chemical intermediates to maximize the use of biomass and reduce the cost of converting lignocellulosic plant sugars to alkanes and alkenes for biofuels at less than $3 per gasoline gallon equivalent (< $3 GGE).

Products

- https://doi.org/10.1021/acsomega.1c00448

- https://doi.org/10.1126/sciadv.1603301

Carbon fibers and composites

Partners

Sponsor

University of Tennessee Research Foundation, USDA

Synopsis

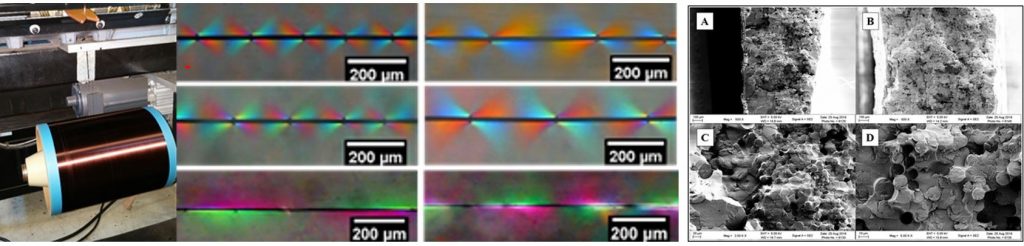

Recent advances in the past several years demonstrated the ability produce lignin from our EvolUTIA process that can melt and spin as a carbon fiber precursor. These carbon fibers come from 100% pure lignin sources from a process designed specifically to provide melt-processible lignin. Melt spun fibers from the EvolUTIA process provide the precursors for carbon fiber-based composites. These carbon fibers demonstrated inferior single carbon-fiber properties to commercial PAN fiber; however, lignin-based carbon fibers showed superior interfacial shear properties to commercial fibers. We accomplished these properties without adding sizing or coupling agents in the composites (Harper et al., 2018). In supporting Prisma’s ongoing efforts to develop products for composite applications from purified kraft lignin, we propose the following approach to create lignin-based carbon fibers. We believe, if successful, these lignin-based carbon fibers will be amenable for a host of composite applications, such as short fiber extruded and injection molded thermoplastics, along with randomly oriented molded products.

Products

- Hosseinaei, O.; Harper, D. P.; Bozell, J. J.; Rials, T. G., Role of physicochemical structure of organosolv hardwood and herbaceous lignins on carbon fiber performance. ACS Sustainable Chemistry & Engineering 2016, 4 (10), 5785–5798. https://doi.org/10.1021/acssuschemeng.6b01828

- Meek, N.; Penumadu, D.; Hosseinaei, O.; Harper, D.; Young, S.; Rials, T., Synthesis and characterization of lignin carbon fiber and composites. Composites Science and Technology 2016, 137, 60–68. https://doi.org/10.1016/j.compscitech.2016.10.016

- Hosseinaei, O.; Harper, D. P.; Bozell, J. J.; Rials, T. G., Improving processing and performance of pure lignin carbon fibers through hardwood and herbaceous lignin blends. International journal of molecular sciences 2017, 18 (7), 1410. https://doi.org/10.3390/ijms18071410

- Yue, Z.; Vakili, A.; Hosseinaei, O.; Harper, D. P., Lignin-based carbon fibers: Accelerated stabilization of lignin fibers in the presence of hydrogen chloride. Journal of Applied Polymer Science 2017. https://doi.org/10.1002/app.45507

- Harper, David Paul, et al. “METHOD OF PRODUCING CARBON FIBERS AND CARBON FIBER COMPOSITES FROM PLANT DERIVED LIGNIN AND ITS BLENDS.” U.S. Patent Application No. 15/799,240.

Graphitic nanocarbons from biomass lignin for energy storage

Sponsors

USDA NIFA Nanotechnology, ORNL

Partners

Dr. David Keffer, Dr. Orlando Rios, Dr. Valerie Garcia-Negron, Dr. Dayton Kizzire, Dr. Jianlin Li, Advanced Photon Source, National Synchrotron Light Source II, Oak Ridge National Laboratory

Synopsis

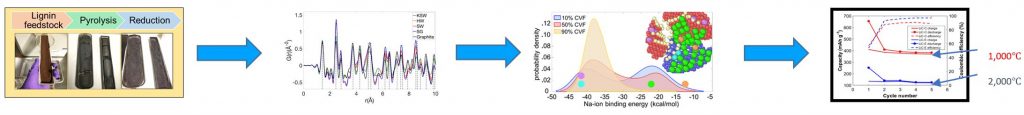

We engineered and produced new nano-graphite materials from a renewable resource, lignin. Lignin’s physiochemical features and graphitization processing conditions make nanoscale graphitic domains with varying morphology. We observed the interrelationships between lignin’s physicochemical structure as derived from botanical sources and extraction conditions. This starting lignin structure highly impacts the resulting carbon structure and performance properties. During this project, we were able to: 1) engineer lignin fractions with varying physiochemical structures for carbon manufacturing, 2) discern the impact of carbonization and crystal growth during carbonization in lignin-gas environments, and 3) provide a detailed description of the nanoscale and mesoscale structure of the carbon material through the use of a hierarchical model to interpret neutron and x-ray scattering data. From the structural model of the carbon composite, we determined the relationship between the starting lignin and processing conditions with the performance of Li and Na ion batteries.

Products

- García‐Negrón, Valerie, et al. “Processing–Structure–Property Relationships for Lignin‐Based Carbonaceous Materials Used in Energy‐Storage Applications.” Energy Technology 5.8 (2017): 1311-1321.

- Valerie García-Negrón, Dayton G. Kizzire, Orlando Rios, David J. Keffer, David P. Harper. Elucidating nano and meso-structures of lignin carbon composites: A comprehensive study of feedstock and temperature dependence, Carbon, Volume 161, 2020, Pages 856-869, ISSN 0008-6223, https://doi.org/10.1016/j.carbon.2020.02.010.

- Dayton G. Kizzire, Alexander M. Richter, David P. Harper, and David J. KefferACS Omega 2021 6 (30), 19883-19892DOI: 10.1021/acsomega.1c02787

- Dayton G. Kizzire, Alexander M. Richter, David P. Harper & David J. Keffer (2021) Lithium and sodium ion binding in nanostructured carbon composites, Molecular Simulation, 47:10-11, 878-887, DOI: 10.1080/08927022.2020.1800689

- Kizzire, Dayton G., García‐Negrón, Valerie, Harper, David P., and Keffer, David J. Local Structure Analysis and Modelling of Lignin‐Based Carbon Composites through the Hierarchical Decomposition of the Radial Distribution Function. Germany: N. p., 2022. Web. doi:10.1002/open.202100220.

- Valerie García-Negrón, Stephen C. Chmely, Jan Ilavsky, David J. Keffer, and David P. HarperACS Sustainable Chemistry & Engineering 202210 (5), 1786-1794DOI: 10.1021/acssuschemeng.1c0596

Alternative materials for power generation in riverine environments (SHARKS – ARPA-E)

Partners

Dr. Orlando Rios, EMRGY, Stanford, Premier Energy Holdings

Synopsis

Emrgy, Inc., a pioneer in commercializing hydrokinetic power systems, is teaming with Premier Energy Holdings, Stanford University, and the University of Tennessee, Knoxville, to develop highly innovative solutions to low-cost, distributed clean energy generation. The project will implement “dynamic tuning” of the hydrokinetic turbine system to optimize performance across variable water flow conditions and implement newly developed control algorithms at the system level to optimize array performance. Successful implementation of the technology platform can deliver low-cost energy of $0.07-0.10/kWh depending on deployment location. Broad deployment of the technology platform in riverine, tidal, and manmade canal resources can displace 1-2 Quads/yr of traditional carbon-based generation and displace 150-300 gigatons of carbon production. Phase I of the project will focus on fluids modeling the riverine environment to provide insight into the impacts of water depth and velocity on turbine performance. Phase II Technical tasks focus on designing dynamic tuning elements in the rotor and flume sub-systems, new materials development for substitution of stainless steel and/or traditional concrete, power system development to improve utility or microgrid operation, and module-level and cloud-based system-level controls development. Phase IIS will build upon sub-scale prototype testing, and the fabrications of a full-scale 20-30kW twin-turbine tested in a suitable riverine environment. At UT, we deliver new, low-cost, durable materials to function in these harsh environments.

Bone regeneration

Partners

Dr. David Keffer, Dr. Stephen Chmely, Dr. Madhu Dhar

Synopsis

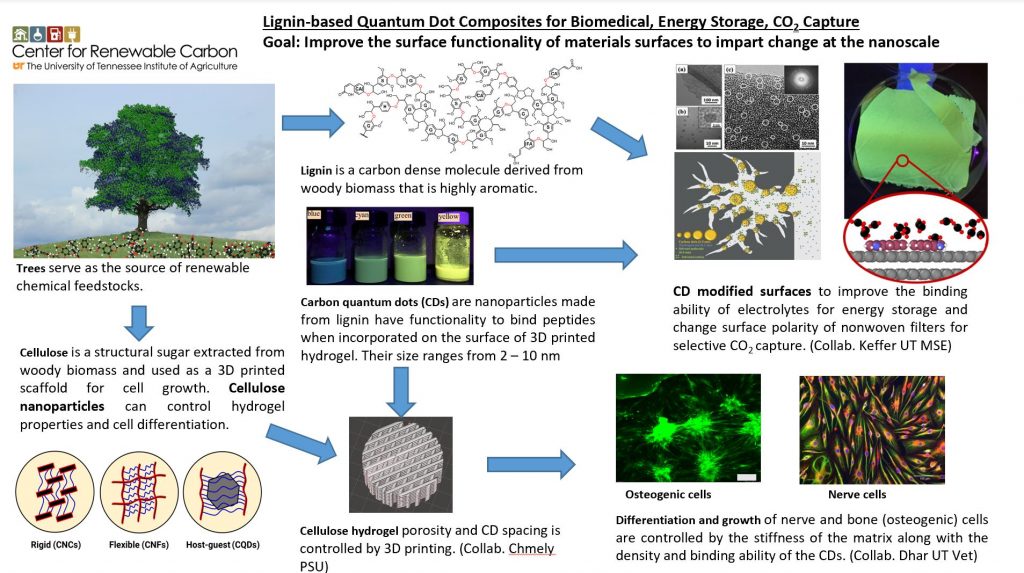

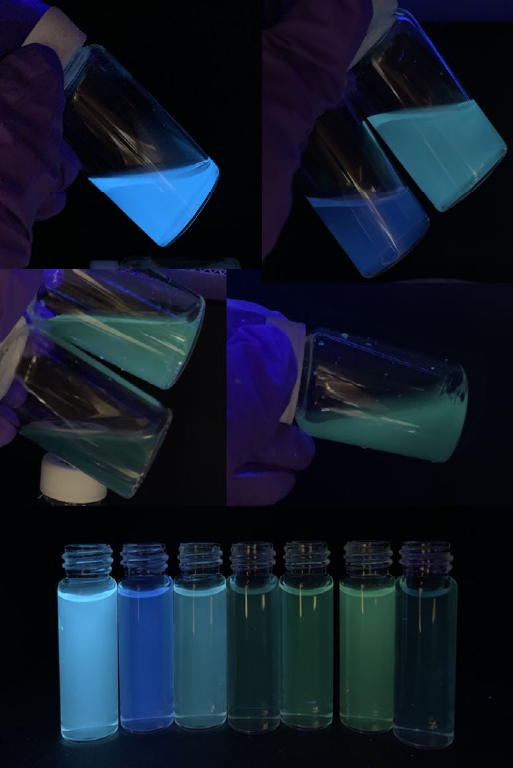

We have created novel biobased hydrogels and passivated graphitic carbon materials in our labs (CQDs) that we believe in having far-reaching applications in biomedical applications. Further, our global objective is to create valuable revenue streams for biorefineries by diverting a small amount of cellulose and lignin to materials for improving health outcomes for humans and animals. Our central hypothesis is that lignin-based CQD-cellulose hydrogel nanocomposites with engineered functional features will control cell response, reduce variability, and improve clinical outcomes in regenerative medicine. We base our hypothesis on our expertise in graphitic carbon, biomaterials, modeling, and regenerative medicine. Our project aims are:

Aim 1: Produce lignin-based carbon quantum dots. Our working hypothesis is that we can take advantage of lignin’s natural aromatic structure to develop nanographitic particles passivated with polar functionality that binds proteins to assist tissue regeneration.

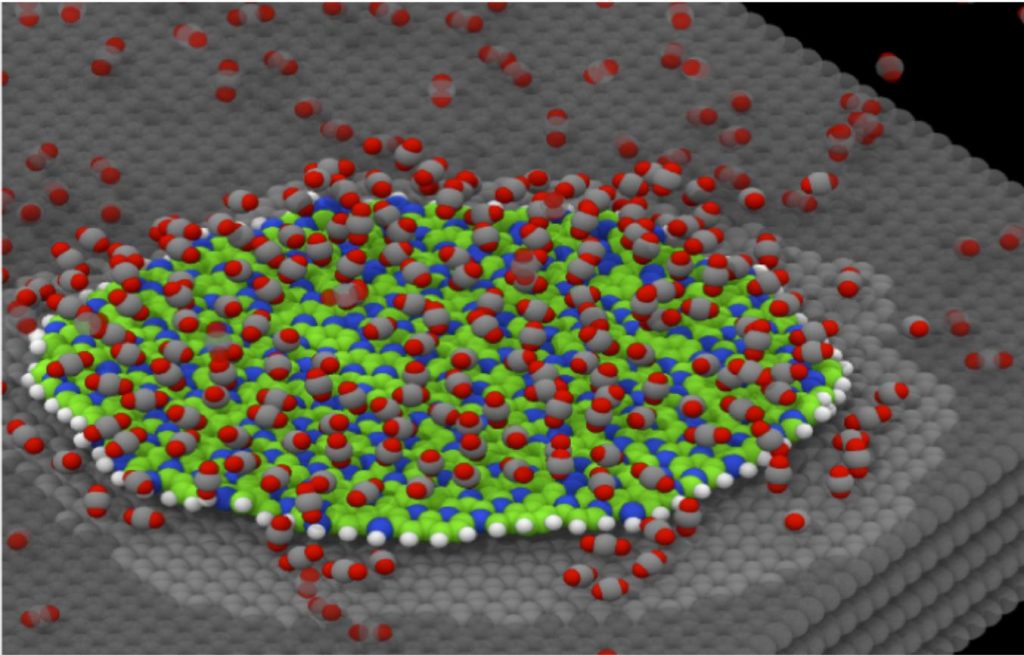

Aim 2: Predict material protein binding and function. Our working hypothesis is that molecular dynamic simulations will predict the variation in RGD binding sites when CQDs spacing and CQDs functionality in a hydrogel matrix.

Aim 3: Produce cellulose hydrogel-CQD composite 3D printed tissue scaffolding. Our working hypothesis is that we can build off our ability to print a biocompatible hydrogel framework with dispersed CQDs.

Aim 4: Evaluate cell behavior in vitro. Our working hypothesis is that scaffold structure and topography will demonstrate a specific arrangement of RGD motifs, which guides cell adhesion, migration, and differentiation.

Selective CO2 Sequestration in Lignin-based Carbon Composite Membranes Via Nanoscale Engineered Quadrupole Moments of Adsorption Sites

Partners

Dr. David Keffer, Dr. Xianfeng Ma

Sponsor

USDA NIFA 2021-08984

Synopsis

We are synthesizing lignin-activated carbon fibers (LACFs) decorated with carbon quantum dots (CQDs) to selectively capture carbon dioxide gas from combustion processes. Uniquely, we are tailoring adsorption sites of LACFs to exploit the much larger quadrupole moment of carbon dioxide relative to other flue gases, such as nitrogen and oxygen. Quadrupole difference is used industrially to preconcentrate oxygen in commercial air separation. LACFs are decorated with engineered CQDs adsorption sites. Usually costly, we use CQDs in this work synthesized from an inexpensive raw material (kraft softwood lignin) via a novel process, both simple and economical in design. A high-throughput modeling effort is currently identifying optimal CQD architecture (size, functionality, and extent of heteroatom doping) for target LACF/CQD membranes based on a binding strength indicator. Top candidates will be synthesized and tested for adsorption selectivity. We are testing the hypothesis that we can synthesize LACF/CQD membranes tailored to achieve carbon dioxide selectivity and a cost-point attractive for large-scale deployment. By testing this hypothesis, we are gaining a fundamental understanding of the processing-structure-property-performance relationship of LACF/CQD resulting in the development of a practical membrane. We aim to achieve this through four targeted project aims: 1) make LACFs and CQDs, 2) determine the physicochemical composition of LACF/CQD membranes, 3) compute and evaluate selective binding of carbon dioxide, and 4) assess membrane performance.